My friend John came over last week with a stack of 2x6s that have been sitting in his yard for awhile and we spent the day making one of Italian artist and furniture designer Enzo Mari’s tables.

A few years ago a reader tipped me off to Mari’s book Autoprogettazione, a difficult to translate neologism that means, literally, “self-design”. The book (free download here) contains a suite of furniture that Mari describes as a “project for making easy-to-assemble furniture using rough boards and nails.” With just rudimentary tools, pretty much anyone could use his book to furnish their own house. John and I built the base of this table in a day and I added the top the next day. This is significantly faster than the fussy hardwood arts and crafts stuff I usually make, which can take months to complete just one piece.

You don’t need a wood shop to make Mari’s furniture. That said, John and I were able to reclaim some of his twisted 2x6s using my jointer, planer and table saw. But here’s where things get confusing. European readers please correct me if I’m wrong here, but when Mari calls for a 25mm x 50mm piece of lumber he means literally that, what would be 1-inch by 2-inches in our convoluted imperial measurements. The problem is that a “1×2” on this side of the pond is actually 3/4-inch by 1 1/2-inch. The luxury of having woodworking tools is that I can plane down larger pieces of wood to make any dimension that I need, so we were able to make the 25mm x 50mm stock Mari calls for from our larger “2x6s”. But if you’re not fortunate enough to have these expensive tools, I think it would be easy to make this same table with slightly thinner wood, fresh from the lumber yard, without any significant sacrifice in strength.

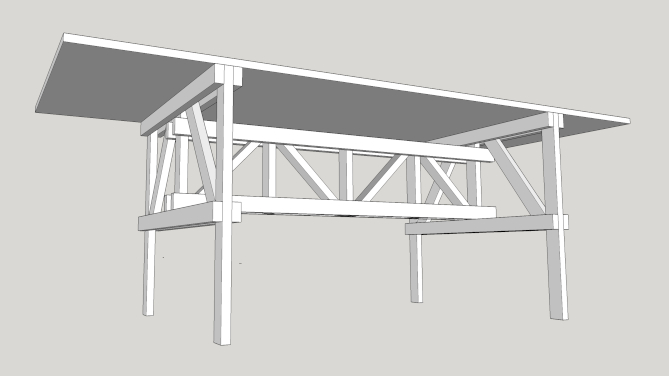

Mari’s designs take their inspiration from American house framing which replaced earlier timber framing methods. Balloon framing, and its more fire-safe 20th century replacement, platform framing, democratize construction and put building in the hands of anyone with a hammer and nails. The clever thing about Mari’s furniture is that it exposes the framing that’s normally hidden in a way that’s both aesthetically pleasing and functional, a bit like Frank Gehry’s early work. Mari’s furniture is based on triangular bracing that he imagined could be applied to any piece. He imagined that if you wanted a custom piece you could use this principle to make anything, hence the notion of “self-design”.

Mari struggles with many contradictions in the text that accompanies the designs. Will a table inspired by framing appeal to workers who actually frame things or just well to do hobbyists such as myself? Probably the latter. He also points out that industrially made furniture requires less material than the examples in this book.

I experienced my own contradictions making this table. Using reclaimed lumber meant the base was free but the decking material used for the top (it’s an outdoor table) was expensive. And my little modernist experiments in furniture–this table and my Gerrit Rietveld chairs–live outside, while a Medievalist arts and crafts fantasy plays out in the furniture I’ve build for the inside of the house. Such is the fate of attempts at revolutionary design within our post-modern age. Everything gets subsumed within a vast parade of styles and one can easily imagine this table on sale at Urban Outfitters at your local mall. Mari, who we lost to COVID in 2020, had the genius and grace to acknowledge the contradictions in his own work while not letting this discourse get in the way of making objects of usefulness and beauty and helping others to have nice things at a reasonable cost.