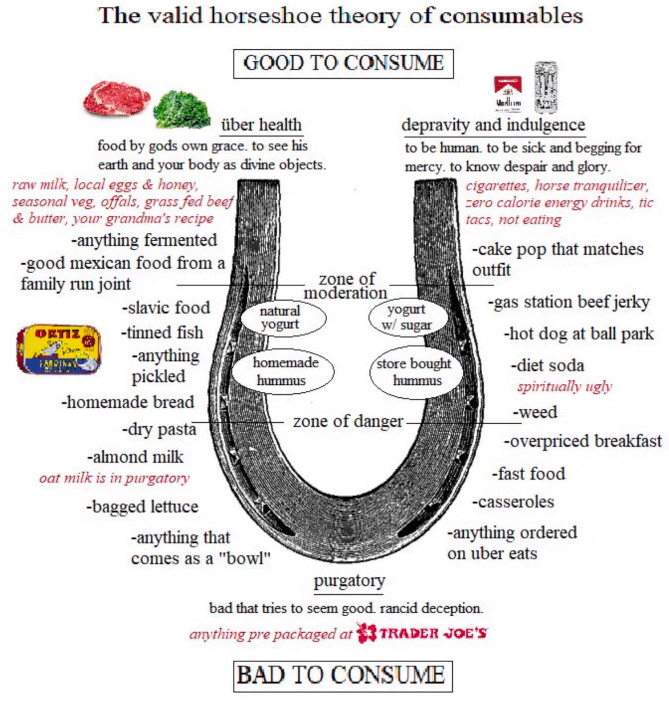

Meme found on the interwebs (not sure where). Totally agree about Trader Joe’s!

On the Origin of the Bass Face

A school for “radical attention”

The rock’s the star: meditative film about a Cornish stone goes global

A Kali Mirch Paneer Pasta Recipe from Pijja Palace

Pentagon’s Budget Is So Bloated That It Needs an AI Program to Navigate It